production to installation service Adhering to the business principle of mutual benefits, Zhenhan play have set up cooperation in 120 countries with5000+ projects ,We have had a reliable reputation among our customers because of professional services, qualityproducts and competitive prices.

Get In Touch

Trampoline parks have evolved far beyond being just a place for children to jump.

Today, they are immersive family entertainment centers — blending fitness, sport, and social play into one dynamic indoor experience.

For investors and park owners, however, excitement is only one side of the story.

Behind every safe and successful trampoline park lies one critical factor: quality manufacturing.

At Zhenghan, we understand that the real foundation of a profitable trampoline park is not only its design but the precision engineering behind every spring, frame, and jump mat.

In this article, we’ll take you behind the scenes of modern trampoline park equipment — exploring how it’s made, what makes it safe, and how to identify true manufacturing quality.

A well-designed trampoline park is more than a set of jump mats — it’s a dynamic ecosystem where every zone plays a specific role in balancing fun, safety, and movement.

Here’s how a typical commercial trampoline park layout is designed to engage guests of all ages:

A Free Jump Zone with interconnected trampolines, giving visitors the freedom to bounce and move anywhere across the floor.

A High-Performance Trampoline Area equipped with professional-grade mats that deliver higher, more controlled bounce — perfect for advanced users and athletes.

A Slam Dunk Zone where basketball hoops meet trampolines, allowing guests to perform gravity-defying dunks safely.

A Dodgeball Court designed for competitive team fun, combining sport, coordination, and laughter.

A Foam Pit or Airbag Zone that provides a soft and safe landing space for flips and aerial tricks, with options tailored to budget and maintenance preferences.

A Ninja Course and Climbing Wall Section offering modular obstacle challenges that test strength, agility, and balance for older kids and adults.

A Toddler Soft Play Area separated from the main jumping zones, using smaller trampolines and cushioned play features for children under three years old.

Each section is thoughtfully arranged to maintain smooth activity flow, reduce crowding, and keep visitors constantly engaged — something Zhenghan’s design team prioritizes in every custom trampoline park plan.

This is where the expertise of a true manufacturer becomes visible.

Every trampoline system, no matter the design, relies on a few core components that determine its safety, performance, and durability.

The frame is the skeleton of the entire park.

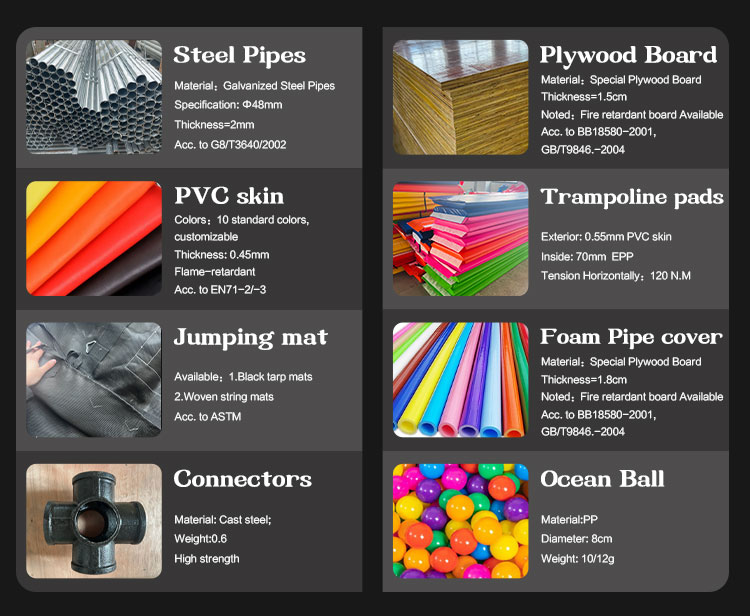

Zhenghan uses galvanized steel pipes (Ø48 mm, 2 mm wall thickness) manufactured in accordance with GB/T 3640/2002 standards.

Each component is precisely cut and welded by certified professionals, then coated with anti-rust spray to ensure long-term structural integrity — even after years of heavy use.

All Zhenghan springs are made from high-carbon piano wire (JIS G 3522 standard).

This ensures superior elasticity, tensile strength, and fatigue resistance.

Each spring is engineered for consistent, responsive bounce — maintaining its performance even under years of commercial operation.

Made from high-strength polypropylene (PP) and produced under ASTM standards, Zhenghan’s trampoline mats offer:

Excellent water and UV resistance

High tensile strength

Long-lasting elasticity

These mats maintain their stability and bounce through countless jumps every day.

Safety padding is often overlooked — but it’s what keeps every jumper safe.

Each Zhenghan pad features:

1.5 cm fire-retardant plywood board (BB18580-2001 / GB/T 9846-2004)

70 mm EPP foam for impact absorption

0.55 mm PVC cover with anti-wear and color-retention coating

This multi-layer construction ensures reliable protection, comfort, and easy maintenance.

Each attraction adds its own excitement and target audience.

Here’s how Zhenghan optimizes the most popular ones:

Foam pits provide a traditional soft landing at lower initial cost.

Airbags offer easier cleaning and faster turnover — ideal for parks seeking higher efficiency.

Reinforced trampoline mats and professional-grade hoops allow guests to dunk like NBA stars safely.

Each lane is spaced for collision-free, continuous play.

Zhenghan provides AR trampolines, LED reaction walls, and spider walls — integrating digital play into physical activity.

We pre-install wiring and frame supports to simplify installation of interactive add-ons.

This is where Zhenghan stands apart.

As a source manufacturer, we don’t just assemble — we engineer from the ground up.

Our in-house design team converts every client’s vision into 3D engineering drawings.

Every beam, bolt, and pad is digitally simulated for a perfect fit before production starts.

Every component goes through a strict quality control checklist:

Load-bearing and weld tests

Surface and coating inspection

Pad fitting verification

Full pre-shipment installation trial

By the time your equipment ships, it’s already been assembled, tested, and verified.

Safety is not a selling point — it’s a promise.

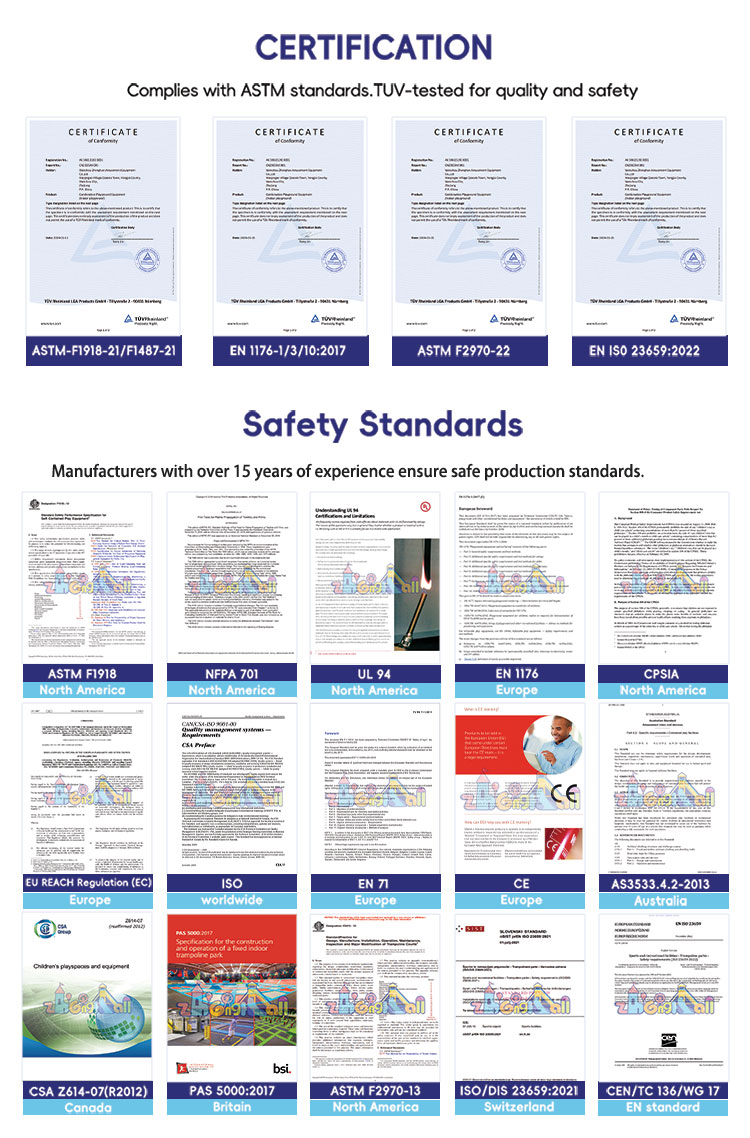

All Zhenghan trampoline park equipment complies with the latest safety standards:

ASTM F1918-21 / ASTM F1487-21 – Public play equipment design and safety performance

ASTM F2970-22 – Trampoline court design, manufacture, and operation

EN 1176-1/3/10:2017 – European playground safety requirements

EN ISO 23659:2022 – General safety management for indoor play and amusement facilities

👉 Certificates and material test reports are available with every order to verify conformity and quality assurance.

Q: How long does trampoline park equipment last?

A: With proper maintenance, Zhenghan’s systems typically last 5–8 years before any major component replacement.

Q: Where is your factory located? Can we visit?

A: Our production base is in Zhejiang, China, and clients are always welcome to visit.

Q: How can I identify high-quality trampoline park equipment?

A: Look for thick galvanized steel, consistent welding, strong bounce, and dense safety padding.

Any shortcuts here will directly affect safety and lifespan.

Building a trampoline park isn’t just about installing equipment — it’s about building trust, safety, and long-term value.

By working with a manufacturer who understands both engineering and entertainment, you ensure that every jump your customers take is backed by precision design and certified safety.

At Zhenghan, we bring over a decade of expertise in trampoline park design, manufacturing, and global installation.

From concept to completion, our goal is to make your park stand out — safely, beautifully, and profitably.

Ready to bring your vision to life?

👉 Contact Zhenghan’s engineering team today for a custom trampoline park design proposal and detailed quotation.

Let’s create a park that jumps higher — together.

Copyright © 2024 Wenzhou Zhenghan Play Equipment Co.ltd